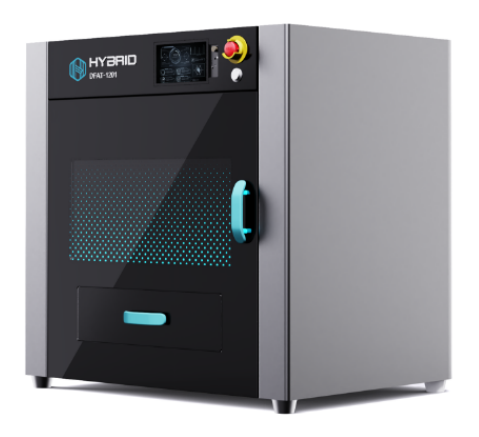

LCR Module

- Desktop Flexible Automatic Tester

- DFAT1201

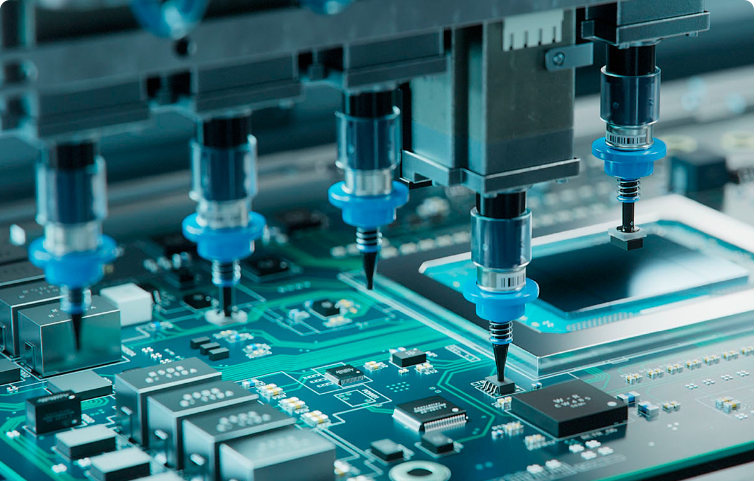

DFAT is a desktop flexible automated test equipment based on flying probe technology, meticulously developed by Hybrid in response to market demands. This product, with its micron-level high-precision positioning and exceptional flexibility, can easily handle testing requirements for circuit boards of various sizes and shapes. It requires no dedicated fixtures and supports rapid programming and testing, making it particularly suitable for prototype design and small-batch production phases. Furthermore, it integrates multiple electrical testing functions and is equipped with a highly sensitive CCD camera, ensuring precise optical positioning and inspection. The DFA system not only accelerates the research, development, and production processes of electronic products but also plays a crucial role in repair diagnostics. It is an ideal choice for improving work efficiency and reducing costs. With this innovative product, Hybrid Test accurately responds to market needs, helping the industry to continually move forward.

- Features

- 受到全世界的信赖

-

- Compact

- DFAT's structure is more compact,offering greater motion space within the same volume,providing more possibilities for miniaturized spatial designs.

-

- Light

- With the same number of probes, the overall weight is only 5% of that of traditional flying probes.

-

- Quick

- DFAT provides a more concisearchitecture,delivering a largeroperational space within anequivalent volume, thus amplifying the potential for compact spatial configurations.

-

- Flexible

- The DFAT product is compact insize and has short cables, whichresults in low signal attenuation,making it highly expandable andcapable of integrating a varietyof instruments and equipment.

- 可扩展模组

- 受到全世界的信赖

-

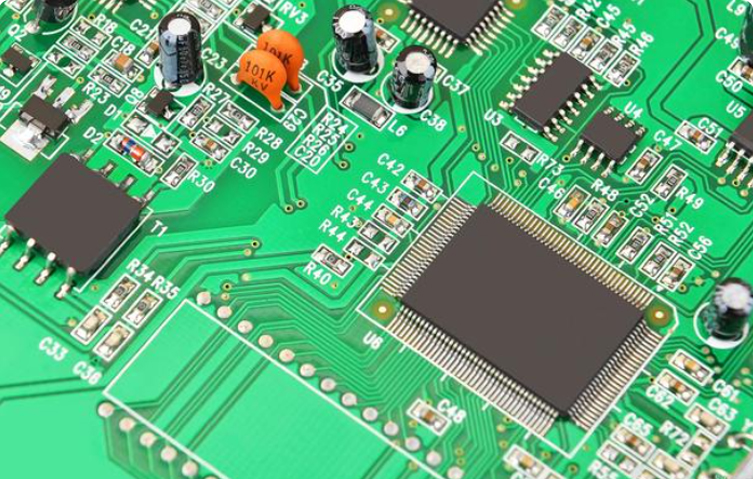

- LCR Module

- LCR testing is used to measure the parameters of inductance (L),capacitance (C), and resistance (R).it assesses the electrical characteristics of the tested object,and is commonly used for qualitycontrol of electronic components and circuits.

-

V/l Module

-

OBP & Bscan

- OBP & Bscan

-

※ OBP is used to program or configure chips to achieve specificfunctions or operations. lt is a stress testing process applied to chips to ensure their reliability andfunctionality under high-stress conditions.

※ Bscan is used for testing through achip's boundary scan chain toverifying the internal connectionsand functions of integrated circuitchips.

-

OSC&RF Test

-

AOI

- AOI

- Vision inspection is used to detectand analyze the assembly quality anddefects of surface components of electronic products through camera systems and image processingtechniques. it is commonly used forquality control and defect detectionon production lines.

- Application Scenarios

- 提供专业的烧录技术和客户定制化的在线烧录解决方案

-

- LAB & RD

- In research and development and prototypinglaboratories, DFAT is primarily used for functionatesting and quality control of circuit boards.

-

- Military Defense Electronics

- The application of DFAT in the field of militarydefense contributes to enhancing the performanceand reliability of military equipment, therebystrengthening national defense capabilities.

-

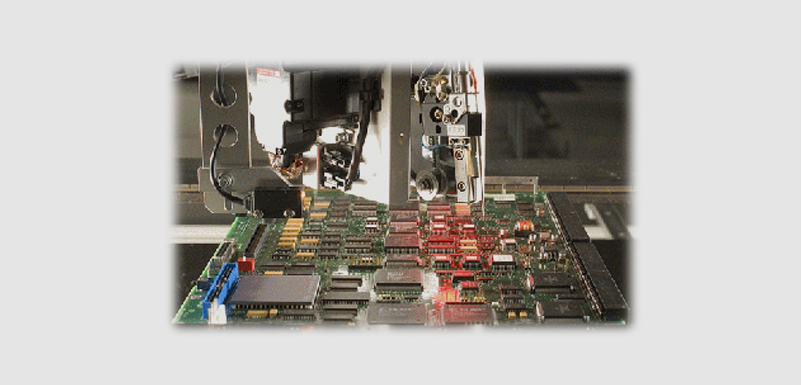

- Repair & RE

- DFAT plays a key role in the maintenance and RE ofcircuit boards. lt is particularly useful in identifyingand repairing issues on PCBs, making it an essentiatool in the field of electronics repair.

-

- NPI

- DFAT plays a crucial role in the repair andtroubleshooting of circuit boards. lt is particularlyuseful for identifying and repairing issues on PCBs,making it an essential tool in the field of electronicsrepair.